Design of an Advanced Analytics System for PLNT

PLNT, a leading global manufacturer of premium car tires, encountered a significant challenge in their production process. The company operates 24 factories across 13 countries, marking a massive scale of operations. To enhance their production analytics and leverage Internet of Things industrial solutions, they sought to develop a bespoke system capable of sophisticated data analysis and visualization to identify and address production bottlenecks. However, existing market solutions fell short in meeting their complex needs. This is where the Singula team was brought into the picture, tasked with crafting a unique analytics system design.

The Challenge

The main hurdle was the enormity and diversity of data generated by hundreds of machines performing millions of operations daily. PLNT needed a system that could not only collect and integrate this vast amount of data but also provide actionable insights. The goal was to transform raw data into a structured, data-informed design to boost efficiency and reduce downtime.

Solution: Tailored Analytics System Design

We embarked on the design of equipment monitoring system that would cater to the needs of PLNT. This system was to serve as a cornerstone in their industrial internet of things case study, providing a data driven UI/UX design that could adapt to the nuances of industrial production.

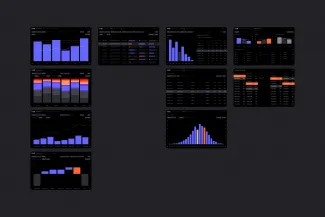

OEE Data Analysis

We developed a section within the system dedicated to overall equipment effectiveness analysis. This allowed various departments to generate reports assessing equipment efficiency, thus enabling top management to gain a holistic view of production health. This interactive data analytics application was pivotal in highlighting inefficiencies and pinpointing areas for improvement.

Monitoring System User Interface

The "Phase In" feature of our solution provided real-time updates on every production stage. By integrating a monitoring system user interface, we facilitated immediate recognition of process status via color coding—green for on schedule, red for delays. This graphical user interface of the monitoring system was instrumental in providing at-a-glance insights into production flow.

Cycle Time & Maintenance Indicators

What is more, we introduced sections for cycle time and maintenance indicators. These areas focused on machine performance and maintenance needs, directly feeding into the web-based interface for equipment monitoring system. By implementing a human-machine interface, operators could see live statistics and adjust their actions based on real-time data, a quintessential human machine interface example.

Impact: A Paradigm Shift in Production Monitoring

The custom solution crafted by the Singula team marked a paradigm shift for PLNT. Through our IoT integration, the plant transitioned from a traditional to a data visualization-empowered operation. The new system established a model for future internet of things industrial solutions.

Conclusion: Setting a New Industrial Standard

The collaboration between PLNT and Singula team has set a new benchmark in the domain of industrial internet of things. The success of this project underscores the importance of bespoke solutions in large-scale industrial operations. Through this equipment monitoring system development, PLNT has not only improved its production efficiency but also paved the way for future innovations in the industry.